Dattasai Technologies

ISO Certified, Customer Focused – Excellence in Every Product

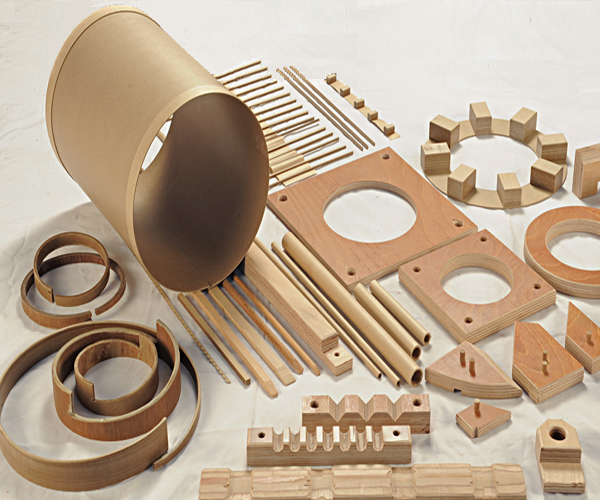

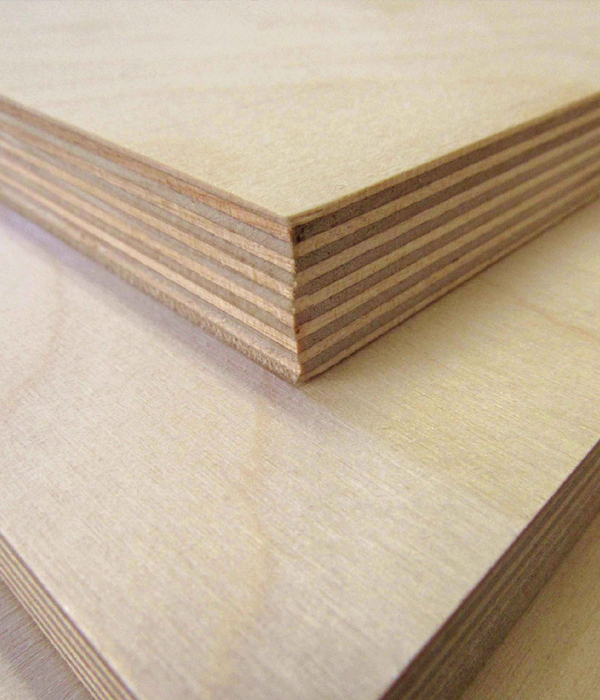

Since 2015, Delivering Precision in Insulation Kits Worldwide

Dattasai Technologies

ISO Certified, Customer Focused – Excellence in Every Product

Leading the Way with Trusted Insulation Solutions and Unmatched Quality

Dattasai Technologies

ISO Certified, Customer Focused – Excellence in Every Product

Commitment to Quality, Passion for Innovation